Portal systems

Download brochure → ––––––––– Request a quote →

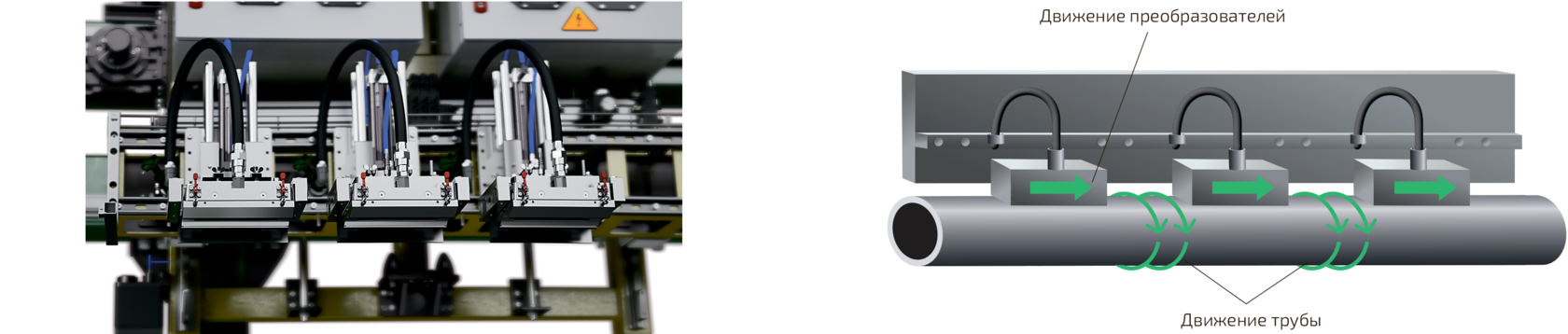

The automated inspection system of portal-type is designed for ultrasonic testing (AUT) of pipes and round bars made of various grades of steel with diameters ranging from 60 mm to 920 mm.

Inspection objects:

- Oil-grade pipes according to API 5CT and 5L standards

- Seamless and welded pipes

- Boiler tubes

- Round bars

- For pipe inspection:

- For bar inspection:

- Linear transducer movement with rotating test object

- Coupling methods: Immersion, gap, or jet

- Electronics options: Multi-channel UT or phased array (PA) technology

- Water supply synchronized with transducer motion

This ensures precise defect detection in pipes and bars with high efficiency.

- Carrying Portal (Gantry)

- Platform with measurement system

- Acoustic block with ultrasonic transducers

- Pipe rotation rollers

- Cabinet for ultrasonic flaw detectors

- Pipe rotation rollers in defect marking position

- Defect marking system

- Video monitoring system

- Calibration bench

See also