WS Inspector

Girth weld inspection scanner with Zone Discrimination Technology

Download brochure → ––––––––– Request a quote →

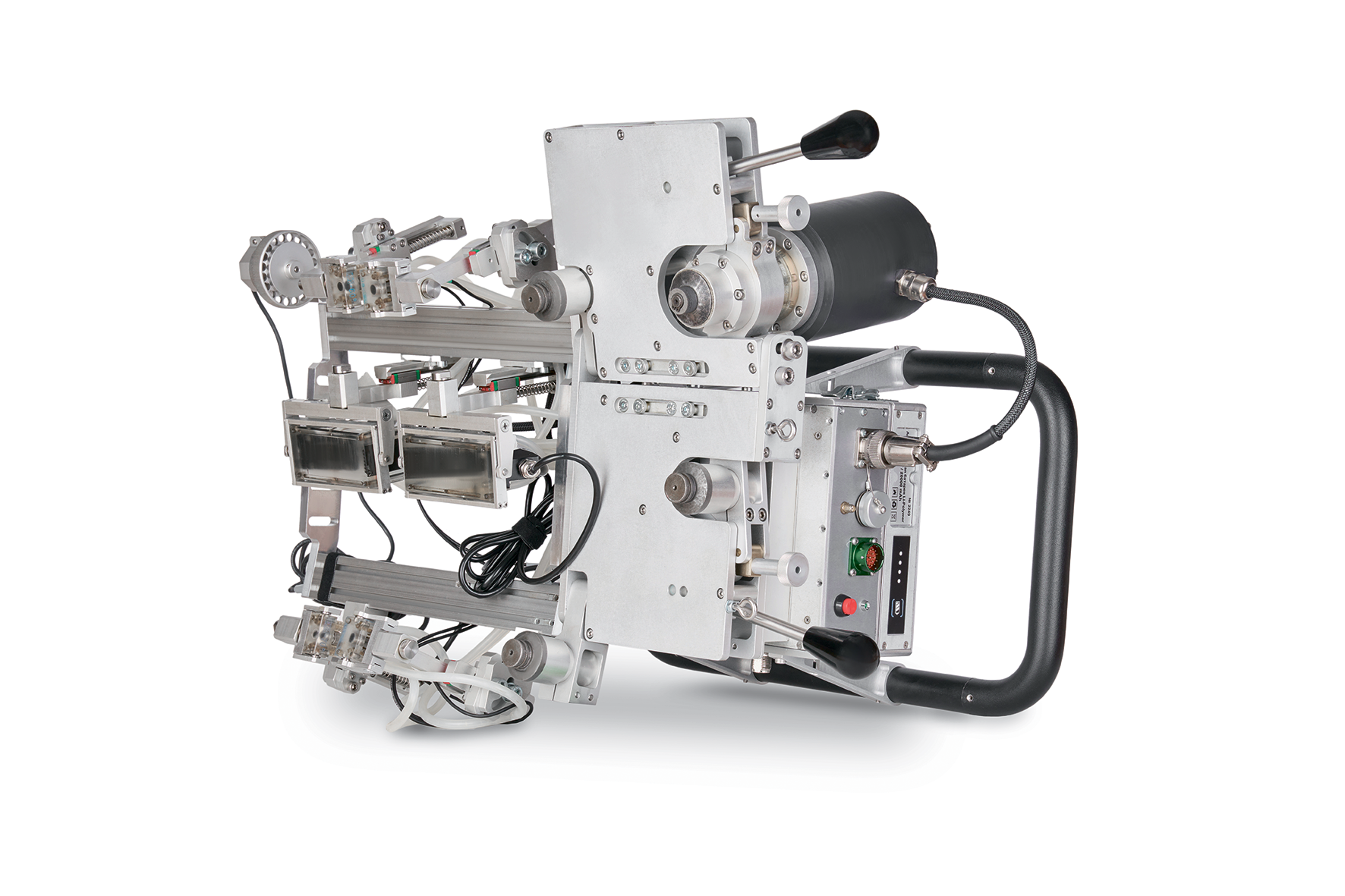

The WS Inspector is a fully automated girth weld inspection system that combines Phased Array (PA) and Time-of-Flight Diffraction (TOFD) technologies with intelligent zone discrimination for unparalleled defect detection accuracy.

Designed for high-speed pipeline inspections, this lightweight (17 kg) system delivers real-time data processing, autonomous operation, and ASTM E-1961 compliance – making it the ultimate choice for precision weld assessment.

Download brochure → ––––––––– Request a quote →

The WS Inspector is a fully automated girth weld inspection system that combines Phased Array (PA) and Time-of-Flight Diffraction (TOFD) technologies with intelligent zone discrimination for unparalleled defect detection accuracy.

Designed for high-speed pipeline inspections, this lightweight (17 kg) system delivers real-time data processing, autonomous operation, and ASTM E-1961 compliance – making it the ultimate choice for precision weld assessment.

pitch-catch, TOFD.

✔ Allows creation of individual ultrasonic beams for each weld zone using only 2 PA transducers, focusing on areas with most frequent defects. Each inspection zone corresponds to each weld pass (every 1–3 mm).

✔ High Spatial Resolution with PA Method.

✔ TOFD Method for Evaluating Defect Sizes and Geometry.

✔ Automated scanning at 100 mm/sec – 3x faster than conventional systems

✔ Intelligent drive system maintains stable speed and acoustic contact in every position on uneven surfaces

✔ Additional carabiners for cable support reducing strain on connectors, thus extending the system’s lifespan and cable integrity.

✔ Self-contained power – All components feature hot-swap batteries

✔ Levers for securing the scanner on the belt, adjustable for various band widths

(80–120 mm).

✔ Ultra-lightweight (17 kg total) with IP65-rated rugged casing

✔ Automated couplant distribution uses 60% less fluid (0.5-1L per 1420mm pipe)

✔ -30°C to +50°C operational range – Built for extreme environments

✔ Automated couplant distribution uses 60% less fluid (0.5-1L per 1420mm pipe)

✔ -30°C to +50°C operational range – Built for extreme environments

Feature — Specification

Techniques: Zone Discrimination, PA, TOFD, Pulse-Echo

Size: Full scanner w 50 x h 30 , length depends on the size of attached frame

Aquisition unit 11 x 24 x 20 cm (with battery)

Weight: Full scanner 17 kg /Acquisition unit 6 kg

Pipe diameter range: 530–1420 mm (dn 500–1400); <500 mm optional

Scanning speed: Adjustable (up to 100 mm/sec)

Operating temperature: –30 °C to 50 °C

IP Rate: IP 65

Cable length: 30 m

Connectivity: Ethernet / WiFi (optional)

Voltage: Internal battery power

Power consumption: 360 W

Warm-up time: No

Connectors: 2 Amphenol (PA ) / 8 LEMO (conventional UT)

GPS Optional

Techniques: Zone Discrimination, PA, TOFD, Pulse-Echo

Size: Full scanner w 50 x h 30 , length depends on the size of attached frame

Aquisition unit 11 x 24 x 20 cm (with battery)

Weight: Full scanner 17 kg /Acquisition unit 6 kg

Pipe diameter range: 530–1420 mm (dn 500–1400); <500 mm optional

Scanning speed: Adjustable (up to 100 mm/sec)

Operating temperature: –30 °C to 50 °C

IP Rate: IP 65

Cable length: 30 m

Connectivity: Ethernet / WiFi (optional)

Voltage: Internal battery power

Power consumption: 360 W

Warm-up time: No

Connectors: 2 Amphenol (PA ) / 8 LEMO (conventional UT)

GPS Optional

Core Components

— Universal frame for 7 transducer blocks (2 PA + 4 TOFD + encoder)

— IP65 sealed with hot-swap battery

- Motorized Scanner Platform (17 kg)

— Universal frame for 7 transducer blocks (2 PA + 4 TOFD + encoder)

- UT Acquisition Unit (6 kg)

— IP65 sealed with hot-swap battery

- Couplant System

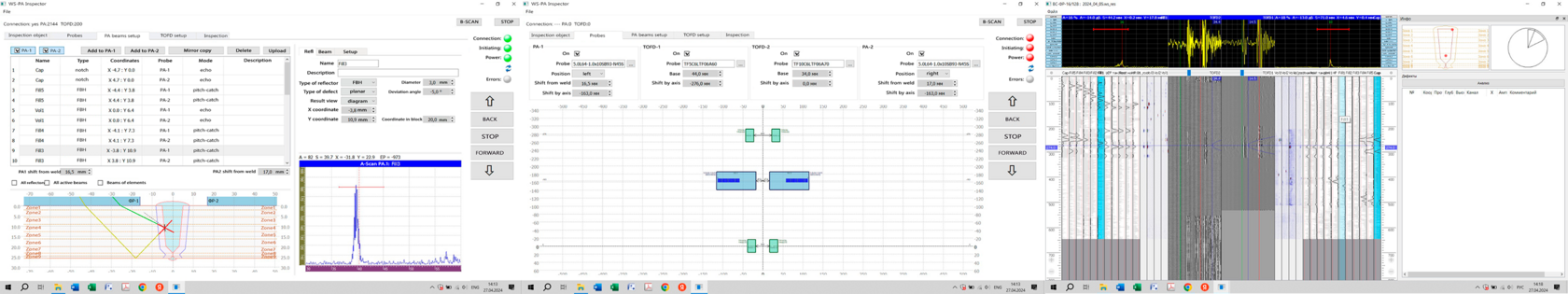

System Configuration Software

allows users to finely tune system parameters such as channels and beams configuration, sensitivity levels, weld discrimination and geometric settings. It includes specialized utilities to simplify equipment setup, like:

✔ Weld Constructor

✔ Control Zones Configurator

✔ Scanner Configurator

✔ Automatic Beam Configurator for generating focal laws

✔ Database of Standard Reflector with Sizes for each inspection zone

✔ Calibration block design

✔ Guidance through calibration and sensitivity adjustments

Data Analysis and Reporting Software

✔ Defect Analyzer – AI-assisted flaw classification

- Color-coded amplitude diagrams

- Virtual weld cross-sections

- Automated defect coordinate mapping

✅ Industry’s fastest scanning (100 mm/sec)

✅ Zero blind zones with micro-zone discrimination

✅ 50% less couplant vs. conventional systems

✅ ASTM E-1961 compliant out of the box

✅ Fully autonomous – No external power needed

✅ Zero blind zones with micro-zone discrimination

✅ 50% less couplant vs. conventional systems

✅ ASTM E-1961 compliant out of the box

✅ Fully autonomous – No external power needed

See also